In this article, we take an honest look at 10 key advantages of autonomous mobile robots and how they can help your business grow.

First though, let's define what an AMR actually is.

What is an autonomous mobile robot?

Autonomous mobile robots (AMRs) are vehicles that operate without human control or intervention.

AMRs are often used in material handling and in fulfilment environments. While they are often confused with automated guided vehicles (AGVs), there is a difference: AMRs typically move dynamically around any obstacles they encounter (employing so-called 'obstacle avoidance'), while AGVs will “stop and wait”.

AMRs also generally carry lighter payloads and are usually smaller than AGVs.

Definitions done then, let's dig into the 10 key benefits of AMRs.

1. AMRs are quick to install and modify

Since AMRs are generally based on natural navigation technology such as ANT, they are quick to install. There are no permanent infrastructure changes required, so robot commissioning is quick and interruptions to your day-to-day operation should be minimal.

While traditional automated guided vehicles might require physical lines to be laid on the floor, or reflective laser targets to be professionally installed high up on the walls, vehicles that navigate using natural navigation need only a few reflective stickers at most (e.g. in areas where there is a lack of permanent infrastructure features visible).

Getting your AMRs up and running for the first time is likely to take a matter of days while modifying routes and robot actions later is even quicker.

2. AMRs are safer than manual vehicles

Automated mobile robots are significantly safer than manual vehicles.

AMRs travel at consistent speeds, use controlled movements, and are equipped with certified safety systems. They must comply, for example, with safety regulations such as EN 1525 (“Safety of Industrial Trucks, Driverless Trucks and Their Systems) and ANSI 56.5:2012 (“Safety Standard for Driverless, Automatic Guided Industrial Vehicles and Automated Functions of Manned Industrial Vehicles”).

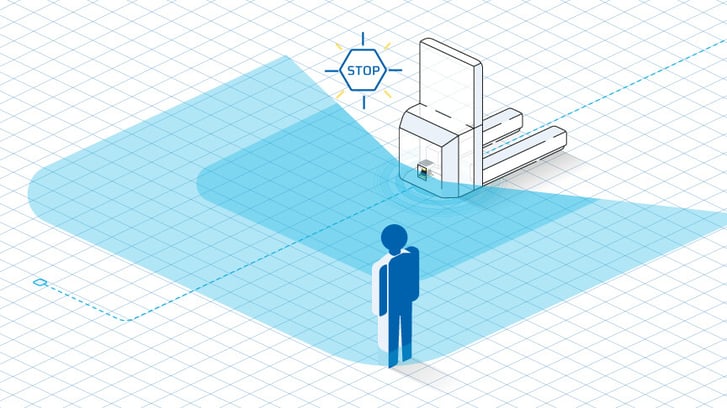

AMRs are generally equipped with LiDAR safety scanners, which detect any object (or vehicle or person) in the robot’s safety field.

If something is detected in this safety field, the AMR will stop and, most likely, find an alternative route (called ‘obstacle avoidance’).

Unlike humans, AMRs do not get tired: they will never make a fatigue-induced error.

As a bonus: because robots are unlikely to get damaged, or cause damage, they can reduce the cost of stock damage and vehicle repairs.

Note: the most dangerous time in an AMR's life is when this solution is being introduced on-site. With thorough, in-depth staff training, however, this risk can be significantly reduced.

3. AMRs get the job done every time

AMRs are a highly efficient transportation solution. They simply do what they are programmed to do each and every time. It sounds too simplistic, but really, how many humans can really say they’re 100% consistent in their own work?

Knowing that your vehicles will work as programmed every time means:

- You can count on zero, or minimal, damage to stock and materials (including the robots themselves)

- Your AMR will not get tired, take sick leave, go on vacation or quit its job

4. AMRs make great cobots

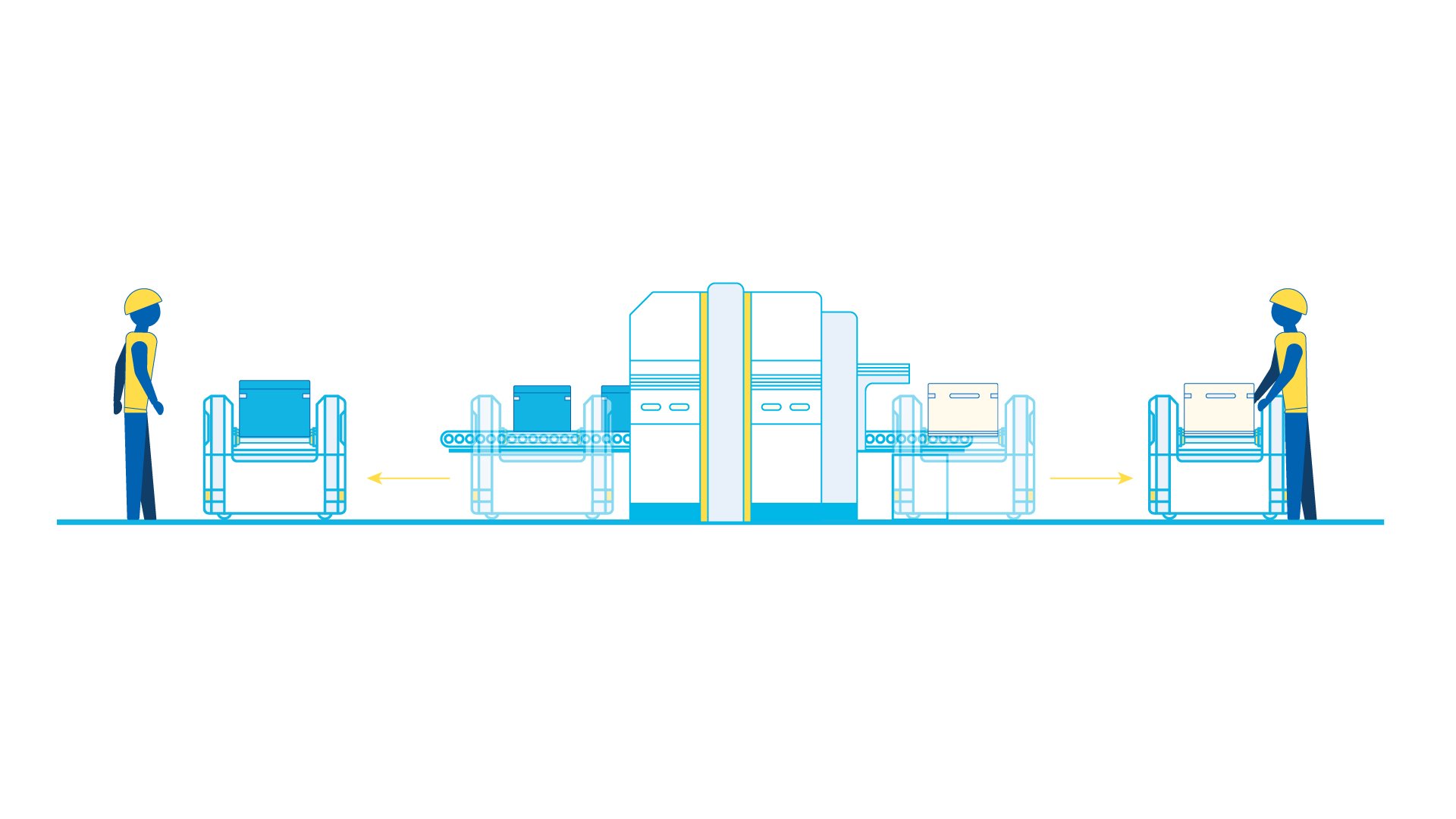

AMRs make better cobots (coworker robots) than larger AGVs. With their typically small profile, they’re less physically intimidating than large vehicles and are less of a perceived danger.

Because AMRs usually do what is perceived as ‘grunt work’ - such as bringing carts to a human picker or moving semi-finished goods from station to station - and this work is largely unskilled, they are unlikely to be perceived as ‘taking jobs’ from your staff.

Day to day, an AMR will never show up late for work, or claim the most prized shifts. While you may see AMRs as tools which make your business run more smoothly, your staff may come to see them as valued coworkers.

5. AMRs free your staff to do (more valuable) work

A common scene in logistics environments is a person stacking empty totes and then ferrying them from A to B.

This workflow is ripe for automation. And automating it will free up a person for work an AMR can’t do – from sorting or picking items, to liaising with suppliers.

Your staffing budget isn’t unlimited. AMRs can help ensure your human staff members earn their money by doing the things only humans can do.

6. AMRs can optimize and reduce staffing costs

AMRs can bring items directly to human packers, meaning less walking back and forth for these staff, and potentially the need for fewer staff overall.

Plus, the ongoing costs of an AMR generally remain consistent over time (budget about 10% of the vehicle’s sticker price each year in maintenance), in contrast to human labor costs which fluctuate widely according to demand.

7. AMRs are “greener”

Almost all AMRs are battery-powered, unlike manually-driven vehicles, which may run on diesel.

Many AMRs are also low-emission, such as the mini™ lite by BlueBotics. This makes them the ideal tool for cleanroom environments such as those required in semiconductor manufacturing.

And unlike humans, AMRs don’t generate emissions by commuting to work, or by using air conditioning.

8. AMRs are easy to scale up

We’ve already discussed how it’s quick and easy to install AMRs. It’s just as easy to add more robots to your business as the need arises.

AMRs can easily be added to, and work within, a connected fleet. AMRs driven by ANT natural feature navigation, for example, can work in a fleet alongside other ANT driven vehicles – even different vehicle types and brands.

Unlike human staff, the availability, cost and quality of AMRs and AGVs is consistent: if you add to your team, you will know exactly what you are getting.

On the flip side, if your operational demands decrease, robots can easily be removed from the fleet. This is even simpler if your AMRs are supplied on a RaaS (Robots as a Service) basis.

9. AMRs enable 24/7 operation

Robots that move around using natural navigation don’t need the lights on to work. If your business is moving towards lights out manufacturing then, AMRs are a great choice.

AMRs can run virtually 24/7, only stopping to charge their batteries. They don’t sleep, get sick or take vacations, and never need to be paid overtime.

In an increasingly connected world, moving towards 24/7 operation can in effect add more hours to the day, allowing you to expand your capacity and respond more quickly to customer demands.

10. AMRs are less expensive over time

Automation with AMRs is not cheap to get up and running. But over time, it is proven to be more affordable than recruiting extra staff to drive more manual vehicles.

Not only do AMRs boost efficiency, but they are a fixed cost - so you can accurately budget them, both now and into the future.

Most AMR users achieve a return on investment on their automation projects within two years – often even quicker.

Explore this for yourself using our ROI Calculator.