We set out to answer these questions - and more - by surveying logistics professionals around the world. You'll find the answers in our exclusive report: Automated Vehicles in Material Handling 2022/2023 Usage Report.

Rising to the challenge

This research was carried out by trade media publisher, Logistics Business, in November and December 2022. Respondents were dealing with a waning pandemic and labor shortages. Global uncertainties (including war in Europe) affected the supply chain, and brought worker safety to front-of-mind.

Mobile robotics and automation are emerging as a solution to some of these issues, and are being adopted in part to rise to meet these very real challenges.

What's now and what's next

This report takes an in-depth look at the current and future state of automated vehicles. It explores the different types of AGVs and AMRs in use today, the tasks they can perform, and the criteria for choosing an automated vehicle. Plus, we asked logistics professionals exactly how they measure the success of their automated vehicle program.

With respondents from around the world, we have a unique view of mobile automation as it is now. In our respondents' own words, we explore the fears and concerns around adopting automation in the future.

We examine what’s driving the adoption of these new technologies, and highlight predictions and trends for the next decade and beyond.

“This survey confirms our belief that the adoption of automated vehicles will continue strongly for many years, driven by the challenge of hiring and retaining material handling workers, the continued need for increased efficiency and cost savings in challenging global conditions.

We are especially gratified to see such strong current use of natural navigation as users see the value of automating material handling operations.”

Dr. Nicola Tomatis

BlueBotics CEO

Key findings

Key findings in the report include:

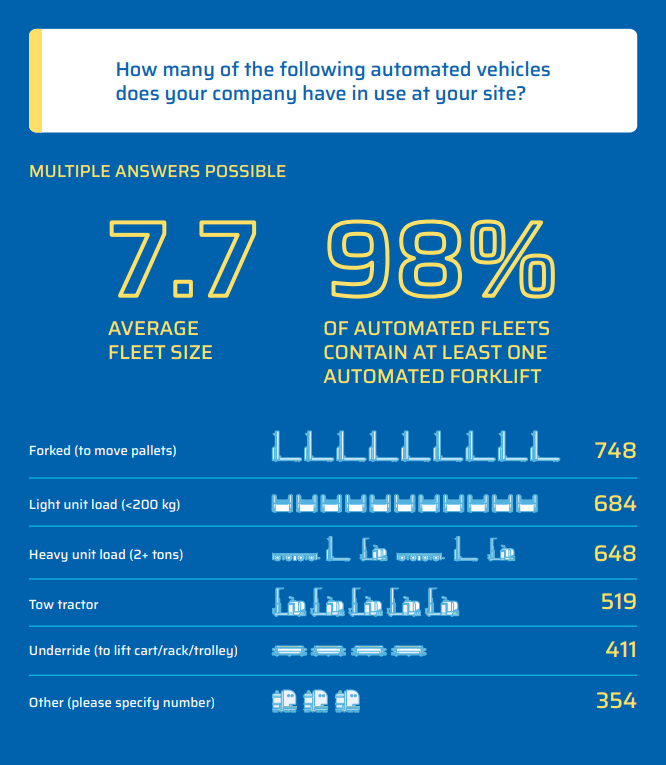

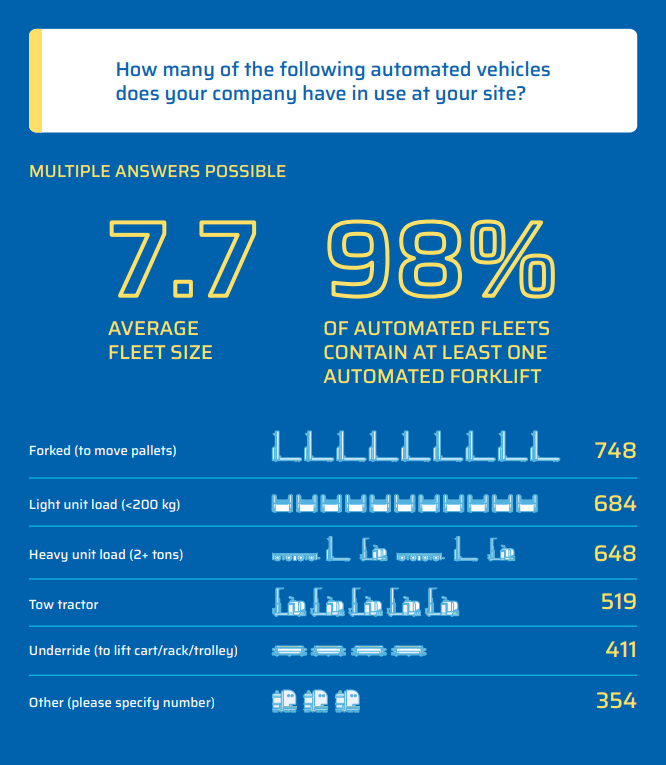

- Automated vehicle use is widespread - and set to grow. More than 70% of the respondents have adopted or plan to adopt AMRs or AGVs and 21% were using self-driving forklifts. The average fleet size was 7.7, consisting mostly of AMRs or AGVs.

- Market growth. 91% of respondents plan to extend their AGV or AMR fleets, with 81% planning to do so within the next two years. Most will purchase between 3 and 10 vehicles.

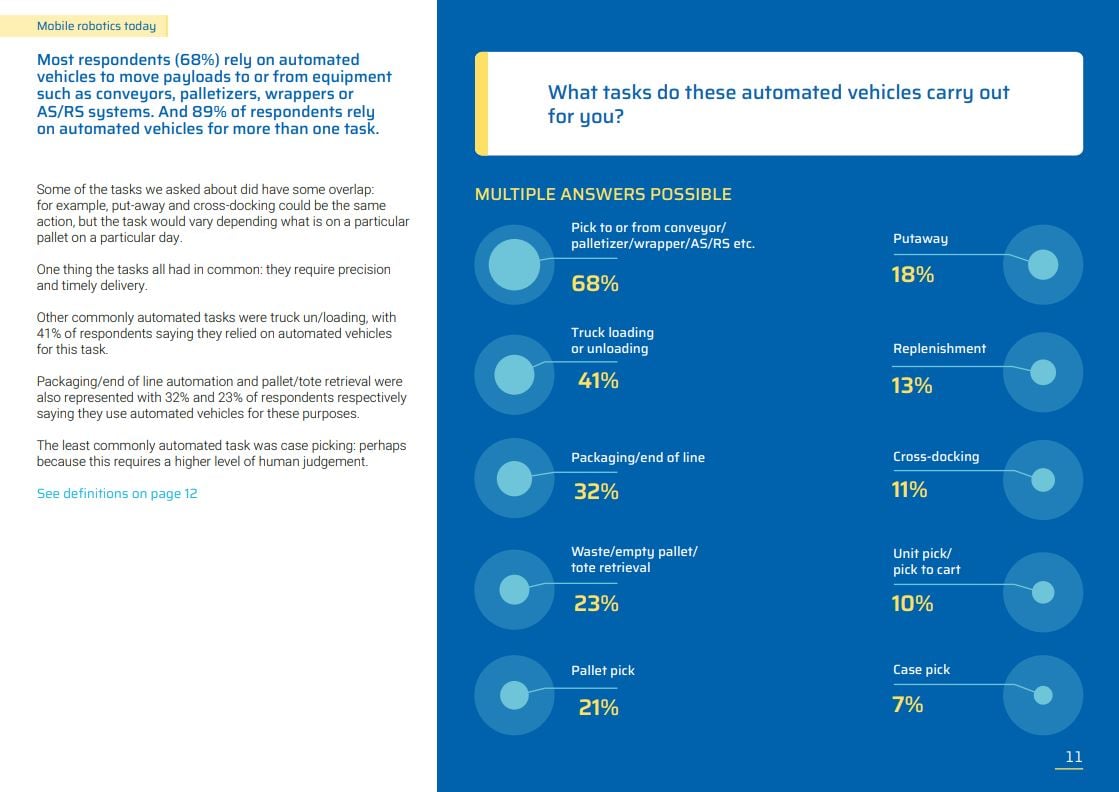

- Diverse uses. Respondents used AGVs to compensate for staff shortages but generally not to reduce headcount. Applications included moving payloads to or from conveyors, palletizers, and wrappers; packaging or other end-of-line applications; pallet toting and retrieval; and picking. About a third cited on-site safety as a reason for adopting automated vehicles.

As well as facts and figures, the report includes insights and commentary from our own team of logistics experts to help interpret the findings.

Sound interesting? Download your copy of the Automated Vehicles in Material Handling 2022/2023 Usage Report.