This article is part of an ongoing series on how to buy different types of automated guided vehicles and autonomous mobile robots. Already published: how to buy a tugger AGV (webinar), how to buy a pallet truck AGV.

The human-operated forklift truck has been a mainstay of manufacturing and warehousing operations for decades. But in these challenging times of shrinking labor pools, rising wages, and in-shoring, many organizations are looking to automate their material handling operations to boost efficiencies and remain competitive.

The goal is simple: use forklift AGVs to ensure dull transport tasks happen reliably, on time, and without causing accidents or expensive damage, while in turn allowing existing human workers to focus on higher value tasks.

With forklift AGVs often costing hundreds of thousands of dollars however, this technology is not an investment to take lightly. The ROI of these systems must be positive (and provable), and installations must run seamlessly from day one, without causing costly delays and downtime.

So, how can your business achieve this? What does best practice look like? And how can you, as a forklift AGV buyer, maximize the chances of project success? We spoke with four leading AGV producers to find out.

Note: The term ‘forklift AGV’ is used throughout this article to describe any forked AGV or AMR system, including automated forklifts/automated guided forklifts/AGFs (i.e., automated versions of existing manual lift trucks).

1. HOW ARE FORKLIFT AGVs USED AND WHY SHOULD YOU AUTOMATE PALLET TRANSPORTS?

Bastiaan Krijger (GO, The AGV Company): Our AGVs can be used in any industry that has a production process, warehousing, or a logistics operation, because this means there are always goods or materials that need moving from one place to another or to be stacked. Today, most of our GO AGVs operate in the food sector, but we have some in the basic metal industry, too.

Martin Ruhland (Kyneos Automation): We see forked AGVs being used most in automotive (OEM and tier one), the chemical industry, and the food and beverage sector.

Hendrik Hoerisch (Oceaneering Mobile Robotics): The industries where our autonomous forklifts are used depends on the vehicle type required. Fork-over-leg (FOL) systems, which are suitable for pallets with an open underdeck, such as EURO pallets, are used across all types of industries; from pharmaceutical and manufacturing production facilities, to warehousing and distribution. By contrast, our counterbalanced AGVs are generally used to move pallets with a closed underdeck, meaning they are used to directly replace manual forklifts, which typically handle heavier loads. These heavier loads are common in sectors like automotive, food and beverage, fabrication, heavy industries, and warehousing and distribution.

Papaleloudis (Liftco): Our forklift AGVs are used in any type of material handling operation involving the transportation of payloads. Our systems can manage standard dimension EURO pallets, industrial pallets, pallet boxes etc., and they can also handle customized payloads thanks to our specially designed forklift attachments such as clamps, grabbing systems etc.

Papaleloudis: AGV forklifts are mostly used to automate either part of a process or an entire process. These processes include the pick-up/drop-off of payloads as a part of an operating task: for example, floor-to floor transportations, from/to conveyors, belts, elevator positions, racking positions, or other custom-made positions. There is also sorting and staging; moving goods to specific areas to follow a production process or store them according to each supply chain flow. We see AGVs doing work-in-progress tasks, like moving raw materials and finished/semi-finished products from one stage of a production process to another to close a loop. And not least, for the loading and unloading of trucks, where specially designed forklifts can transport goods from docking areas into trucks and trailers, and vice versa.

Ruhland: The key processes we see are floor-to-floor transports, floor-to-rack (and vice versa), and especially in our case, truck and trailer loading and unloading, plus the stacking and unstacking of boxes and pallets.

Hoerisch: Mobile robots are typically used to move pallets and other load carriers such as racks and boxes, which contain all kinds of materials, to production lines and to transport finished goods from the end of the line to warehouses or loading docks.

Krijger: In general, most forklift AGVs are used to transport goods from production lines to storage or docking lanes. We’ve also installed them in combination with robot palletisers; the robot palletises the goods and the AGV delivers them to the warehouse. When the robot palletiser starts to run out of pallets, the forklift AGV supplies new ones. This enables a continuous workflow without the need for human intervention.

Ruhland: We see three main reasons: a shortage of skilled workers, the need for plannable transports and processes, and to reduce product damage.

Hoerisch: The primary reason companies automate material handling is cost savings. Automation also significantly increases throughput and operational efficiency through having consistent, reliable transport flows. Many companies are also driven by the need to enhance workplace safety and to mitigate the shortage of qualified manual forklift drivers, especially for 24/7 operations.

Papaleloudis: Companies turn to AGVs for several reasons: a lack of personnel (especially during peak-season operations or in the case of continuous three-shift operations), the cost of damage caused by manually driven forklifts, the need for precise and standardized operations (which manual operators often struggle to achieve), and to conduct high-risk operations, which removes staff from danger. Business continuity is also a driver, as automated processes improve KPIs, since they can be more easily measured and predicted.

Krijger: Companies automate to improve efficiency, boost productivity, and reduce costs. Furthermore, AGVs improve the overall safety on-site: they scan their surroundings to prevent collisions and damage, and they follow predefined routes, creating a more organized and predictable workspace.

Another reason is 24/7 production, while other reasons are related to personnel, whether it’s a labour shortage or the nature of seasonal work, in both cases companies are looking to minimize the need for extra employees. A good example is our customer TOP, The Onion Group (case study). They deal with seasonal work, with the number of employees fluctuating depending on the incoming orders. In this case our AGVs replace the seasonal workers who were previously required to drive the forklifts. That saves on labor costs.

Papaleloudis: These processes were carried out either by manual operators of forklifts or by other mechanical or semi-automated transportation systems such as conveyors, belt paths, carousels, elevators and so on.

> Related: AGV/AMR vs Conveyor – Which is the Right Choice for Your Business?

Hoerisch: Previously, the transport of goods was done with manual forklifts, where operators received their transport orders either from other operators, via paper lists, or via warehouse management system (WMS) screens. It’s important to understand that when deploying mobile robots, it’s not only the transport itself that is automated, but also how the transport orders are generated. With AGV systems this is typically done by interfacing the vehicles with a site’s existing WMS systems or line programmable logic controllers (PLCs).

Krijger: The advantage of AGVs is that they can operate day and night. Unlike human drivers, they don’t get distracted by coffee breaks, nor do they stop to help someone out, so there are no interruptions or other tasks to stop the production process.

We noticed, for example, that at one of our customers an AGV was working at midnight on New Year’s Eve. The AGVs can work while you’re celebrating with your family!

Papaleloudis: Forklift AGVs improve efficiency and productivity in several ways. They offer continuous operation, as AGVs can operate 24/7, taking breaks only for charging. They offer consistent performance, by performing repeatable tasks, precisely. And AGVs offer increased safety, with less traffic in narrow places, fewer errors, less damage, and a lower risk of injury due to there being no human fatigue. AGVs also require less maintenance than manual vehicles.

AGVs also help companies to reduce costs; from labor costs—especially in terms of overtime and night shift costs—to lower costs due to damaged goods, and significantly lower repair and maintenance costs versus human-operated trucks. AGVs also help with process optimization since routes can be carefully optimized, pointless payload movements avoided, and space used more efficiently overall. Lastly, AGVs are a scalable solution; fleets can be easily scaled up or down, and their tasks changed at the click of a button.

Hoerisch: Forklift AMRs and AGVs can improve efficiency by operating 24/7, and they can continue working during breaks or shift changes, times when human operators typically stop. They further enhance efficiency because transport orders are generated automatically, and the supervisory software has algorithms that automatically choose the fastest route. As a rule of thumb, the productivity improvement with AGVs is typically around 10%, due to fewer breaks per day and less labor dependency. Additionally, the downtime of the machines served by mobile robots is typically reduced by 10%.

Ruhland: AGVs drive more safely, and they don’t cause damage to products or buildings. One of our customers reported property damage of around €120,000, per forklift driver, per year! With the AGV, this sum has been reduced to almost zero.

2. HOW DO FORKLIFT AGVs WORK AND WHAT CAN THEY HANDLE?

Hoerisch: Any load that can be handled with forks can be transported by forklift AGVs, ranging from lightweight pallets to off-size heavy metal racks weighing two tons. In the case of different load sizes, some vehicles—like our counterbalanced MaxMover forklift—also offer automatic fork pitch adjustment, which helps different load sizes to be handled by one vehicle.

Papaleloudis: The lifting capacities of an automated forklift usually follow the capacity of the manual forklift chassis the AGV is based on. For example, a pallet truck type chassis will mean the AGV has an average capacity of 2,500 kg and a max. lift height of 150 mm. For stacker and reach trucks, these figures might average 2,000 kg and up to 11,000 mm. Counterbalanced vehicles can usually handle up to 8,000 kg and lift up to 8,000 mm, while very narrow aisle (VNA) AGVs can usually lift 1,500 kg up to 12,000 mm.

Payloads meanwhile typically follow standard dimensions, like EURO pallets, ISO, GMA-USA pallets, and other typical industrial pallets. Otherwise, special forklift attachments can be integrated into the AGV’s design to handle different custom loads.

Krijger: AGV forklifts can carry all types of loads: pallets, pallet boxes, gitter boxes, containers, wooden crates, stacking pallet racks, and more. Basically, anything that has space for the forks to go underneath. As an example, our GO AGVs have lift capacities of 1,000 kg, 1,500 kg, 2,000 kg and 2,700 kg, with a maximum lift height of 5 metres.

We also offer customized forklift AGVs. For one project, for example, we equipped two forklifts—if we can still call them that—with a huge 900 kg gripper. This is used to pick up large carbon anode blocks that are 1,700 mm wide and weigh 1,200 kg. The AGVs take the blocks from the end of the line and stack them on top of each other, up to five metres in height. So really, forklift AGVs can handle many sorts of payload, even drums and barrels.

> Looking to move pallets with AGVs? Try browsing our Vehicle Finder.

Ruhland: We use the BlueBotics navigation system alongside a camera-based navigation technology we developed ourselves.

Papaleloudis: Our Liftco AGVs use natural feature navigation, specifically BlueBotics’ ANT lite+ system. This achieves high precision and has proved very flexible at all our customer installation sites.

Krijger: Our AGVs use BlueBotics. A huge benefit is that this type of autonomous navigation doesn’t require us to adjust the structure of the environment. The LiDAR scanner on top of the vehicle simply scans the fixed reference points to locate itself. Our AGVs also have safety scanners at the bottom, but we don’t use those to navigate because when we’re driving through areas packed with pallets and goods there are few reference points still visible at floor level.

Hoerisch: In the past, our AGVs used magnet grids or reflectors to navigate through a customer’s facility. Today, all our vehicles use BlueBotics’ infrastructure-free navigation technology. This eliminates the need for floor magnets or reflectors, making installation significantly faster; our systems can typically be up and running within 2-3 days, compared to the 3-6 months often required with traditional navigation. Additionally, with the BlueBotics tech, we can quickly and easily make layout changes.

Krijger: Thanks to their safety laser scanners, AGVs detect obstacles and can then drive more slowly or, when really close, immediately stop.

For the staff driving the manual trucks, it’s important they’re informed about the AGVs, because when they know how a robot operates it’s easier for them to work safely and efficiently together in the same space.

Ruhland: Our “sweet spot” is to separate manual and automatic vehicles on-site whenever possible. If this isn’t possible, it’s important to have some kind of “interface” to communicate with manual forklifts, such as light signals, sounds etc.

Hoerisch: It’s obligatory for mobile robots (AGVs and AMRs) to apply the standard EU or US safety norms. On top of the minimal requirements of the ANSI or EN3691 standards, additional 3D cameras or 2D lidar sensors can also be added for additional vehicle safety.

Recently we’ve also implemented something called Elevated Obstacle Detection (EOD). This is a highly precise 3D camera system that actively scans the vertical space and detects obstacles up to 2.3 meters (7.5 ft) above floor height. We recommend this because traditional ground-level safety scanners are incapable of detecting elevated obstacles, such as the raised forks of manual forklifts—unseen hazards that can cause costly collisions, and damage to goods, interrupting a company’s operation.

Papaleloudis: Our AGVs are specially designed to work in mixed traffic environments. They are equipped with safety rated sensors, cameras, and communication networks to coordinate traffic flow and prevent collisions, while at the same time using audible warning alarms and route lighting.

That said, to avoid confusion, all personnel working in the same area as AGVs should be trained on how AGVs interact when an obstacle or a person is detected in their safety fields. And, of course, they should know how to activate an AGV’s emergency stop system when needed. What’s more, speed control measures should also be assigned to both systems (AGVs and manual vehicles) based on a risk assessment study for each specific working space. Finally, signage and the marking of different routes always help people to stay aware, but these measures alone can’t be effective without prior, regular and effective training for those personnel affected.

Hoerisch: Autonomous forklifts include collision avoidance, which means they’re equipped with advanced sensors and navigation systems that allow them to detect obstacles and stop, or even re-route, to avoid collisions. They comply with stringent safety standards such as ANSI/RIA R15.08, which outline specific requirements for hazard identification, risk assessment, and design measures. And, unlike human-operated forklifts, AMRs operate consistently and predictably, reducing the risk of accidents caused by human error.

All our vehicles meet the related ISO norms and even exceed these safety requirements, with not only 360° safety fields but also additional safety features like 2D LiDAR sensors, EOD cameras, and sound modules.

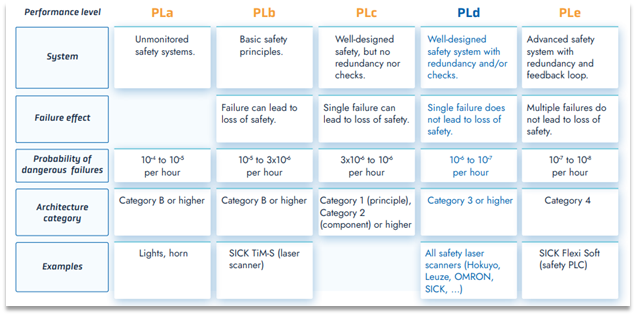

Ruhland: If everything has been planned well, a performance level of PLd is achievable.

Krijger: AGVs are safer than manual vehicles. They have safety scanners, visual and acoustic signals, emergency stop buttons, and they adjust their speed automatically to avoid collisions. We position our vehicles’ safety scanners to provide 360-degree visibility, so there are no blind spots. And just like any other machine or vehicle in Europe, our AGVs are CE-certified.

Papaleloudis: Our AGVs are designed according to ISO 3691-4:2023, ISO 13857:2019 and EU directives EU 2006/42, and 89/240/EEC. They are equipped with second- and third-level safety systems to ensure safe operation in each movement they perform. These systems combine high-tech sensors, safety-rated laser scanners, and machine vision systems that allow them to detect any obstacle or person in order to slow down, stop, or perform an emergency stop. The safety system is never bypassed during operations so that it can prevent any collision that might be related to payload stability, obstacle detection etc.

Papaleloudis: Our AGV forklifts can adjust their approach and correctly align their forks by using ‘Pallet Tracker’, a special feature of our vehicles’ ANT navigation system. In general though, pallets should be placed correctly and according to each AGV’s specifications, in order to avoid extra delays and complexity.

Hoerisch: If a pallet is not positioned correctly, AMRs can detect the location of the pallet and adjust the pick-up using BlueBotics’ ‘pallet tracking’ feature. This feature is especially useful in mixed warehouses and distribution centers, where manual and automatic transports interface. However, picking up pallets from a fixed position is always preferred because it is faster.

Ruhland: The answer depends on the situation but in general yes, this is possible, with a tolerance of up to 30°.

Ruhland: Any type of rack really. It just needs to be accessible, and the aisle’s width must be sufficient. It’s important to know that an AGV requires slightly more aisle width than a manual forklift. AGVs are equipped with a safety scanner and will never collide with an obstacle, but depending on the environment and protection status, slightly more space might be required.

Papaleloudis: AGVs can serve any type of racking system that is compatible with their technical specifications, such as single selective, back-to-back, drive-in and drive-in shuttle.

To choose the right vehicle, you should give the technical and construction details of any racking systems you have installed to your AGV supplier in advance. The best-case scenario is that a racking system can be designed or selected to suit AGV operation prior to the racking’s installation. Like this, limited tolerances can be avoided, allowing the AGVs to work as flexibly as possible.

Last but not least, quality control is always essential. A racking system should be regularly inspected for any failure, especially during mixed operations, and its loads should always be within specifications.

Hoerisch: The racking must be horizontal and the aisle width in front of the rack must be wide enough for the AGV to make a 90-degree turn.

Krijger: It depends on the vehicle. We offer, for example, a fork-over-leg AGV—also known as a stacker—that needs a clear entry space for the fork to go underneath, whereas our counterbalanced vehicles can pick and drop goods from any racking system that provides at least 10 mm of clearance on both sides of the pallet.

Papaleloudis: To work outside, AGVs should be equipped with a navigation system that is capable of such operations (e.g., featuring GPS, GNSS antennas etc.). The producer should also take extra care with the initial design of the AGV, so that its weather- and light-sensitive equipment is properly protected. We’ve found ANT everywhere by BlueBotics to be an applicable and effective tool for performing outdoor operations with satisfactory precision.

If no such indoor/outdoor navigation system is installed, in our experience AGVs driven by natural navigation are still able to work outside, but at limited distances from buildings, and providing Wi-Fi coverage and connectivity is solid so that the connection with the navigation server isn’t lost. And, of course, weather and working environment conditions should permit this type of operation (for example, dusty environments can lead to unexpected errors and downtime).

Ruhland: In terms of working outside, for us it depends. Our expectation for outdoor operation is that the area is at least under a roof, as the reliability of our high-precision sensors and camera technology can only be guaranteed if the vehicle is protected from rain and snow.

Hoerisch: Our current vehicle portfolio doesn’t include an outdoor model; however, we expect to have outdoor applications ready by the end of 2026.

Ruhland: Our vehicles are capable of loading and unloading of trucks from the side (with the neoCATT 3.5) and from the rear (the neoCATT 2.0). We’ve already implemented this successfully in several projects. We use innovative camera technology and AI to identify payloads precisely and to achieve a previously unattainable level of positioning accuracy.

The precise positioning of the truck is not necessary and we can handle a wide variety of goods formats. The loading is basically carried out in a form-fitting manner on the loading area itself. In addition, we can also stack and unstack containers or pallets, which can be necessary for sequence tracking or single-type storage.

Papaleloudis: Our AGVs are able to load and unload trucks by taking advantage of their maximum loading capacity, when certain conditions are met: truck inspection and safe docking/parking procedures must have been first applied; and in the case of heavy weather conditions a Business Continuity Plan should also have been put in place.

Hoerisch: We are developing trailer loading capabilities. We’re running several proof-of-concept projects with our vehicles right now and we expect our first projects to go live by the end of 2025.

3. HOW DO YOU INTEGRATE FORKLIFT AGVs INTO YOUR FACILITY?

Papaleloudis: In our experience the first question should be: which process(es) should be automated? Ideally, AGVs are best for working shifts that require high precision and a continuous flow.

Prior to installation, there are then several key factors to consider by all the departments involved. For example, the facility’s layout should be checked for path and route clearance, and for slab floor tolerance. The team should check that the type of AGV being considered is compatible with racking systems, the requested payloads, and has any additional equipment needed for the requested tasks. Wi-Fi availability, network installations and other system compatibilities should also be checked. At a human level, AGV ‘supervisors’ should be selected and trained to perform any troubleshooting that might be required during day-to-day operation.

A risk assessment must also be carried out to ensure that all safety systems are applied not only to the AGVs but also to the work site (covering training, floor markings, signage, the possible connection of AGVs with fire systems, exit doors, elevators and so on).

Krijger: Well-organised logistics are crucial for a well-functioning AGV operation. Processes need to be properly defined and structured before the purchase and integration of the AGVs. The customer also needs to define pick-up and drop-off points, with this information being provided through their ERP or WMS system.

> Related: Who Integrates AGVs, AMRs and Automated Forklifts?

Hoerisch: My most important recommendation is this: to implement a successful automation program you should involve your entire team—across all departments—from the very start. When implementing AGVs or any robotic system, everybody must be aware that a single robot stopping can impact multiple downstream processes.

The road to automation isn’t always smooth. We’ve noticed many companies face challenges when moving from manual processes to automation with mobile robotics. You often need to rethink factory layouts, infrastructure, and how goods are tracked and traced.

One of the biggest lessons we’ve learned is that standardization really helps. When processes are too complex, they’re harder to automate. We’ve worked with customers who had to break down their workflows into smaller, more manageable steps before we could implement the robots. And in some cases, customers adjusted their processes to better fit automation. It’s all about finding a practical approach that works and adapting both the new technology and the existing processes.

Ruhland: You should remember that AGVs need more space than manual trucks (because of the protective safety fields of their laser scanners), the site’s flooring should be in a good enough condition, and the on-site Wi-Fi network should be comprehensive and perform correctly.

Ruhland: The floor is important. It should not have too much damage, it should not be too slippery, nor should it be too dusty or dirty.

Krijger: Forklift AGVs do have some specific requirements, yes. The ideal temperature for our forklifts is between 5 and 40° C, with humidity below 80%. And inclines or ramps steeper than 5% should be avoided.

Papaleloudis: Yes, all environmental conditions should be verified prior, during, and at the end of the installation of the AGVs. In terms of flooring, flat, optimal surfaces without cracks or holes are required for smooth navigation, plus any inclines shouldn’t affect your vehicle’s stability or performance. Temperature should be considered too, as this can affect the vehicle’s electronic components and battery performance.

Hoerisch: A mobile robot is an automatic machine with minimal floor clearance, which doesn’t allow for steep inclines or big gaps. Our MaxMover machine can deal with inclines of up to 10% and most of the time standard industrial flooring is good enough.

Krijger: AGVs can detect pedestrians, even when they are carrying loads up high, thanks to their safety laser scanners, which are at ankle height. In addition, our AGVs have a tilt function so that the load is tilted against the mast, making it much more stable—remember that the fork of the AGV is located at the back, so when the AGV drives forward with its load, if there is an emergency stop its load will simply fall against the mast. To improve visibility, our AGVs also use projector lights when transporting high loads.

Ruhland: Objects that aren’t properly secured can fall, but the AGV itself is safe around people and cannot injure anyone.

Papaleloudis: Our AGVs are designed to carry full loads at the safest possible height when moving. They only raise their forks when they have safely stopped and are about to pick-up or drop-off their payload. Nevertheless, there is always the possibility of collision, falling loads, or sudden stops due to external factors. That’s why training and qualification procedures should always be applied to all affected personnel, such as cleaning staff, security personnel, visitors, contractors etc.

Pedestrians should always keep a safe distance away from the vehicle, never limit the visibility of its scanners or other obstacle detection systems, and to eliminate risks if there’s a system failure, they must be aware of the vehicle’s emergency stop buttons.

Hoerisch: The answer depends on the stability of the load. In general, staff should stay away from high loads, just as they would during manual operations. One of the features we offer to avoid the risk of loads dropping from a rack is ‘empty drop off detection’. This makes sure the rack space where the AGV is dropping off its load is actually empty, so that no misplaced loads are pushed aside.

Hoerisch: If different loads are transported in one system, our OMR Supervisory Software is aware of which vehicle type can carry which load and automatically sends the correct vehicle to transport that load. It will even automatically adjust the pitch of the forks for the load to be transported.

Ruhland: For larger fleets, we sort the individual vehicle types into groups. Then we select the right vehicle or group depending on the order, load, weight, type of pallet etc. All our neoCATT vehicles are equipped with sensors in the tires that can determine both the load and the load center of gravity. This allows us to rule out overloading.

Papaleloudis: The fleet management software is always interconnected, via our bridging software called Maestro, with whichever WMS, EMS, ERP or other system is in use at the work site. This enables us to provide the requested traceability. Special built-in sensors, barcode/RFID readers etc. can also be implemented to verify mission compliance and to inform Maestro’s user interface.

Krijger: We make sure the same vehicles are running at each customer's premises, so it doesn't matter which mission the vehicle receives. The fork just adjusts its position to suit the load it has to carry.

Krijger: First and foremost, if the customer wants safe and smooth automation, they must ensure that the materials the AGVs are supposed to work with are in good condition. Our GO AGVs have a scanner between the forks that checks a pallet’s placement; if the forks cannot move under the pallet due to damage, the system detects this and stops the operation.

Papaleloudis: AGVs can identify malfunctions that might affect the stability of the payload and eventually the stability of the vehicle during operation. When such a malfunction is identified the AGVs smoothly stop and report the relative error or status message. Extra machine vision systems can also be used to identify more details or to reject the requested mission. Pallet and payload quality control is mandatory for effective AGV projects.

Hoerisch: Slightly damaged pallets are typically not an issue. For example, if the fork pockets are blocked, or if loads have fallen off. the mobile robot will stop automatically. However, with automatic systems it’s always recommended to avoid transporting broken or damaged loads, because these can cause safety issues for the operators.

Ruhland: Heavily damaged pallets should not be transported by AGV as this is too dangerous.

4. WHAT MAINTENANCE AND SUPPORT DO FORKLIFT AGVs REQUIRE?

Hoerisch: Maintenance intervals depend on the vehicle’s usage and are indicated by our OMR supervisory software. Typically, we’re talking about once or twice a year. As a rule of thumb, mobile robotics systems are retrofitted after being used for approximately ten years due to obsolete electrical components, which can extend the lifespan to 15 years, sometimes longer. Some of our customers are still using mobile robots that were deployed over 20 years ago.

Krijger: Our AGVs require minimal maintenance. In dusty environments, safety scanners should be cleaned daily. Otherwise, we perform maintenance twice a year, including oil changes and cleaning control components. That’s it.

The expected lifespan of our AGV systems is at least 50,000 operating hours. That means twenty four years if operating one shift per day, twelve years for two shifts and six years for three. Plus, our entire AGV is modular; we can easily change components so that the AGV runs longer than 50,000 hours.

Ruhland: On one hand, the maintenance required is similar to that of a normal forklift, covering hydraulics, lifting systems, etc. On the other, an AGV’s sensors should be cleaned regularly and its safety equipment checked. The predicted lifespan is easily over ten years.

Papaleloudis: Like all forklifts, AGVs should follow a preventive maintenance program that reflects their working hours. The preventive maintenance of mechanical parts should take place, on average, every 1,000 working hours.

Papaleloudis: The best practice according to our experience is to roll-out the integration in stages. The AGV system should also be seamlessly integrated with a customer’s existing WMS/ERP/MES or other systems for it to be effective.

It’s important to carefully consider which tasks the AGVs should undertake during the initial design phase. Your team should look to understand which KPIs are key to focus on, and later examine what pros and cons you experience after using the AGVs for a year at least, and only after this analysis then proceed to scale up, for example by expanding your AGV operation to cover other processes and tasks.

Krijger: First, conduct a thorough analysis of what needs to take place and where. Then, in mutual consultation, determine the most effective routes to implement this smoothly.

Hoerisch: To avoid disturbing normal production, the complete system should first be simulated and tested, which we do using BlueBotics’ ANT simulation software. The deployment of the first vehicle can then be carried out in the evenings, overnight or on the weekend, after which additional vehicles can be added one by one during ongoing production.

Ruhland: The simple answer is, a current manual process can never be 100% automated. We always have to adapt the process to the requirements of automation. Precise planning is essential to ensure smooth integration, with a defined configuration and simulation.

Ruhland: We offer service trainings, repair trainings, and maintenance trainings.

Krijger: The operators are trained on how to assign missions to the AGV. During that training we also teach them what to do in case of technical errors, such as re-inserting the vehicle into the system. Even then we are always available to answer questions and help them to solve any issues remotely (for which we use the vehicle’s router).

Hoerisch: We offer a variety of different support levels, including a 24/7 Hotline. Standard training for operators is also available to learn our maintenance and supervisory software. We can also customize this on demand.

Papaleloudis: We offer different technical support options to cover customers’ partial or 24/7 requirements. We always have a remote support team available and on-site ad-hoc visits are available on request.

These AGV operators follow a 40–50-hour training program. This ensures they understand: the basic principles of AGV operation, the AGV’s safety system and the risk assessment study that was carried out for their specific site, how to use the vehicle’s emergency stops, how to use its joystick to manually navigate the AGV to its starting, parking or charging positions, if required. We also train them how to troubleshoot of expected errors and status messages, and we train them on the system’s user interface where specific operational requirements may have been set for the company’s specific project (for example, for the insertion/extraction of vehicles, changing priorities, stopping and restarting the system etc.). After this, all our customers’ operators go through oral and written exams to be qualified by our trainers.

5. WHAT SHOULD YOU CONSIDER BEFORE BUYING A FORKLIFT AGV?

Krijger: Probably the ROI. Not everything can be monetised though. Of course, you consider the reduced personnel costs, for example, but ergonomics, safety, and the potential reduction of on-site damage should also be taken into account. Frankly, it gives peace of mind; the fact the an AGV can drive without having to worry about personnel.

> Explore our AGV ROI Calculator

Ruhland: You should have a clear picture of which tasks you want to automate and draw up the required specifications of these tasks. You also need to compare which AGV types are available: which manufacturers, service models, etc.

Hoerisch: When investing in automation, the most important things to look at are safety, total cost of ownership, and how reliably a system can operate over time. We also see that many customers choose AGVs because it’s getting harder to find qualified forklift drivers, especially for night shifts. Another big factor is the need to reduce damage to products, infrastructure, and equipment, with which automation can certainly help. I always advise customers to look beyond the initial price and focus on long-term value, reliability, and how easily they can scale and adapt as their business grows.

Papaleloudis: If we were to summarize, the most important factors when investing in AGV forklifts are: choosing the task that will give the optimum ROI, ensuring the AGVs are compatible with the racking system you have in place (to avoid extra costs), connection with WMS/ERP/EMS or other systems (otherwise what should be fully autonomous tasks will require manual intervention), strategically choosing the right forklift size and type to create a scalable fleet, and making sure the AGVs’ safety systems follow EU legislation and comply with ISO directives.

Krijger: It depends on the situation. For example, there are situations where companies run multiple AGVs 24/7. In this case, an ROI of 2.5 years can be achieved.

Ruhland: It depends on the configuration. With 24/7 or 3-shift production we expect an ROI of between 2 and 3 years.

Hoerisch: The return on investment (ROI) for 24/7 AGV usage typically takes about two years. Various factors influence this ROI, including the initial cost of the AGV, non-vehicle costs such as software, installation, and training, and annual maintenance costs.

Other factors include the cost of the number of shifts worked per day, the number of days worked per week, the number of operators currently working per shift, the annual salary of one full-time equivalent (FTE) operator, labor overhead costs related to onboarding and benefits, the percentage success rate of AGV missions, the predicted productivity improvement percentage, any anticipated reduction in downtime, and available subsidies for replacing non-electric manual forklift trucks.

Papaleloudis: In general, automation projects require a high initial capital investment. However, an AGV investment enriches the culture of organization in many ways.

Working places reach higher levels of safety, performance and business continuity. The risk to personnel is minimized during daily operations, and labour shortages and personnel productivity are no longer a bottleneck for the organization. Training and vehicle maintenance are significantly reduced.

And manpower can be used for more advanced operations, which in turn improves the quality and effectiveness of a company’s finished products. All these factors affect the calculation of ROI in favor of the organization.

Ready to talk forklift AGVs?

Are you interested in automating your business' pallet transport processes? If so, browse forklift AGVs or contact our expert team to book a free consultation.