Automated Guided Vehicle Definition

Let's start by defining what exactly an AGV is and how it is different to an AMR.

An automated guided vehicle or AGV is a mobile robot that follows a series of predetermined instructions, cues or signals to move around a site and complete actions (like picking up or dropping off materials) autonomously.

Are AGVs different to AMRs?

AGVs and autonomous mobile robots (AMRs) are often confused.

Some people in the industry use these terms interchangeably, however, there is a difference. The U.S. safety standard for industrial mobile robots, ANSI/RIA R15.08-1-2020 (R15.08) defines the difference between AGVs and AMRs as “how they traverse the specified operating environment.”

Put simply, an AGV moves through an environment by following predefined guide paths — either virtual or physical — and uses collision avoidance (stopping and waiting in case of a blockage). By contrast, AMRs can set their own paths and use obstacle avoidance to navigate around any blockages.

Generally speaking, the types of AGV listed in this post use the classic AGV ‘stop and wait’ approach to dealing with blockages.

4 Types of AGVs

The following are the most common types of AGV on the market today.

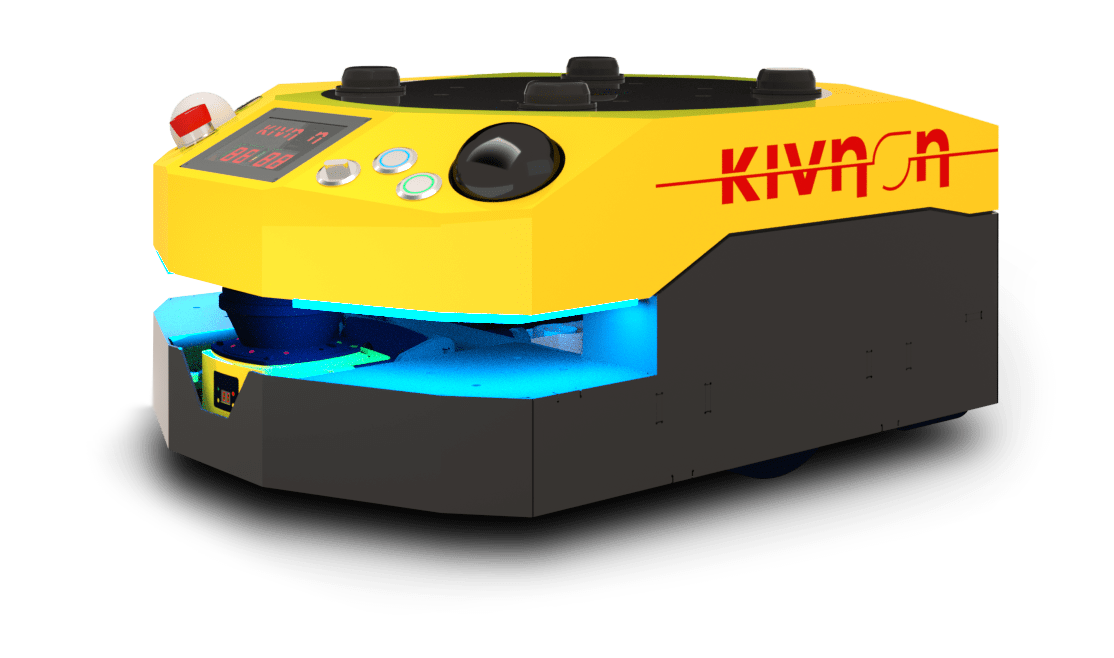

1. Underride AGVs

Underride AGVs drive underneath payloads such as carts and trollies to move these from point to point. Underrides connect to their payloads in a variety of ways, such as via tow pins and lift modules. Some underride AGV models are also capable of acting as tow tractors by hitching to trains of carts.

Underride AGVs are used in material handling and manufacturing applications, for example, to move semi-finished goods between different production stations. They are often deployed in large fleets, most notably in automotive production.

Simple in design, these low-profile robots are flexible and relatively low-cost compared to other types of AGV such as forked models.

You might also hear underride AGVs being called: automated guided carts (AGCs), self-driving carts, under-cart AGVs, or mouse AGVs.

2. Tow tractor AGVs

This type of AGV hitches to payloads such as carts and other logistic trains. Tow tractor or ‘tugger’ AGVs offer towing capacities of up to several tons. And since they can move several carts at one time they offer high throughput. An example use case of a tugger AGV is the transfer of parts to an assembly line.

Many tractor AGVs are actually automated versions of human-driven vehicles. These may also offer hybrid operation, allowing a worker to take over and drive if required.

You might also hear tow tractor AGVs being called: tractor AGVs, tugger AGVs, towing AGVs.

3. Unit load AGVs

Unit load AGVs carry their cargo on top. They are available with different transfer devices, such as conveyors and lift platforms, and are found most often in production and warehouse facilities.

Unit load AGVs are available in many sizes - including custom-designed configurations - and are capable of carrying a diverse range of payloads. They are used to transport everything from light goods and pallets to robotic arms, truck tires and multi-ton steel coils.

You might also hear unit load AGVs being called: unit load carrier AGVs, unit load deck AGVs, and turtle AGVs.

4. Forked AGVs

Forked AGV simply refers to any automated guided vehicle with forks. These vehicles perform similar types of tasks to automated forklifts: lifting and transporting materials and goods, most often pallets.

An important distinction: while automated forklifts (also called automated guided forklifts or AGFs) are robotic versions of existing, manually-driven forklift trucks, forked AGVs are not. Instead, they are designed from the ground up for automated operation only. Therefore, forked AGVs do not offer hybrid operation (they cannot be manually driven if needed).

Numerous types of forked AGV are available, from pallet truck AGVs to counterbalance, reach truck and very narrow aisle (VNA) models. While forked AGVs cost significantly more than their manual forklift equivalents, their efficiency benefits often lead to a significant return on investment being achieved, often in as little as one or two years.

You might also hear forked AGVs being called: fork AGVs, forklift AGVs, and pallet truck AGVs.

Which type of AGV is best for your business?

That depends. The type of AGV which is best for your business depends on the work you do. And while we’ve outlined the four most common types of AGVs, there are a lot of variations within these categories.

To get expert, no-obligation advice, get in touch with our team. Or, browse our Vehicle Finder to find an AGV supplier near you.